Transfert de chaleur et de masse

Fournir un qualité premium, les meilleures performances et de hauts standards de sécurité.

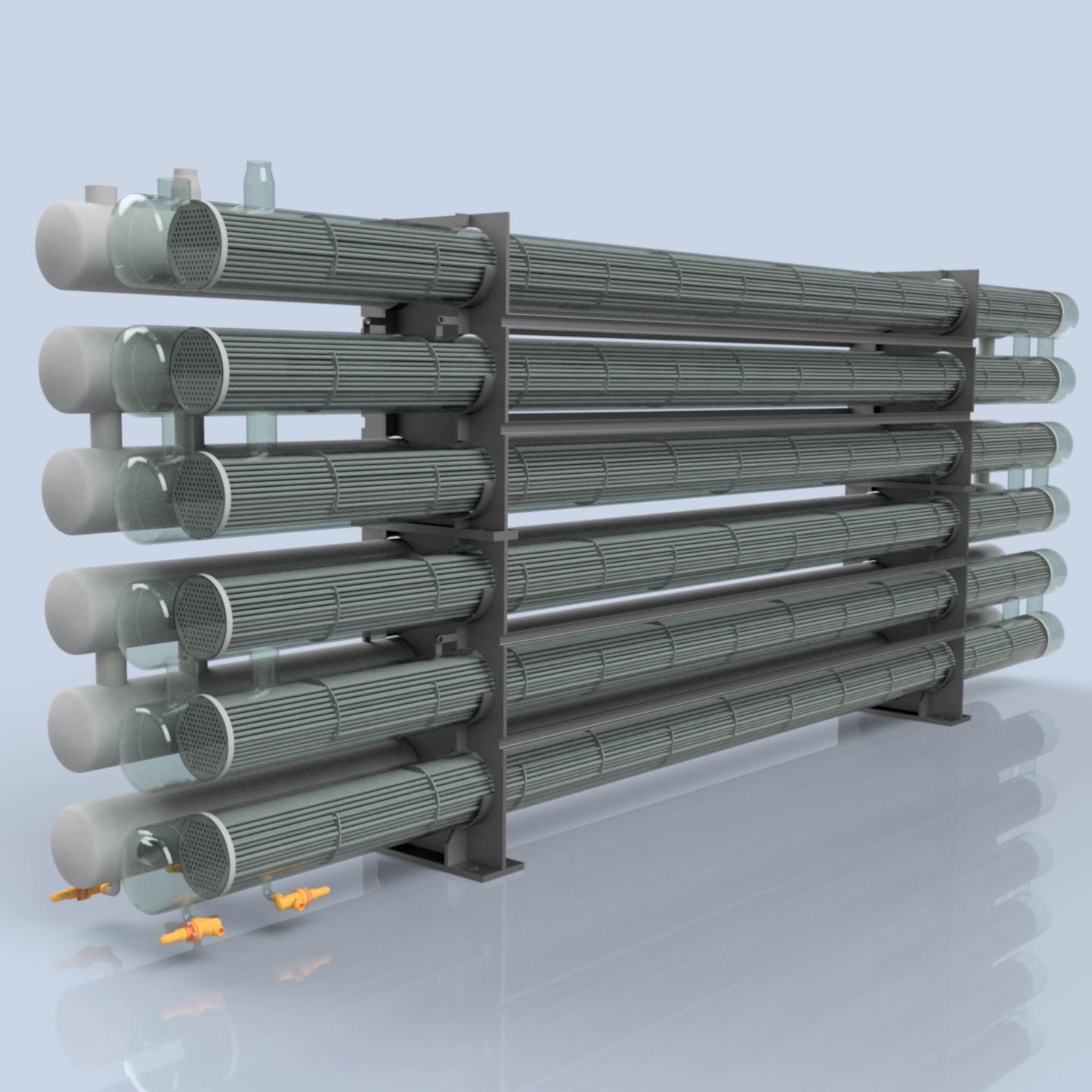

Échangeur thermiques

Des échangeurs de chaleur droits aux faisceaux en U, en passant par les types à calandre et autres, tous nos échangeurs de chaleur sont fabriqués en Europe selon les plus hauts standards de fabrication et soumis à des contrôles qualité stricts, et disposent de toutes les homologations et certifications nécessaires.

Chaque échangeur est conçu et calculé individuellement. Grâce à de nombreuses années d’expérience et à nos propres programmes de calcul thermodynamique et de dynamique des fluides, nous pouvons garantir les meilleures performances et résultats, que ce soit en acier au carbone, acier inoxydable, titane ou autres matériaux.

Domaines d’application :

- Évaporateurs

- Condenseurs

- Désorbeurs / chaudières

- Échangeurs thermiques liquide-liquide

- Économiseurs et autres échangeurs liquide-gaz

- Récupérateurs de chaleur des gaz d’échappement

Nous possédons également une grande expertise dans la conception d’échangeurs pour applications de mélanges binaires.

Colonnes de rectification

Les colonnes de rectifications jouent un rôle majeur dans chaque installation de refroidissement par absorption d’ammoniac.

Au cours des années , nous avons acquis une expérience vaste et approfondie dans la conception de ces colonnes, en utilisant aussi bien des plateaux que des garnissages structurés ou aléatoires.

Cette expertise non seulement nous renforce dans notre capacité à concevoir efficacement et construire chacune des colonnes en fonctions des besoins opérationnels spécifiques, mais aussi nous habilite à délivrer une large gamme de colonnes qui servent de nombreuses applications dans l’industrie chimique.

Ceci inclut, sans être limité à cela, des procédés fondamentaux tels que la rectification des gaz, les laveurs et les colonnes de désorption.

Séparateurs et réservoirs d’ammoniac

En complément des échangeurs de chaleur et des colonnes, nous pouvons être votre partenaire pour la conception et la fourniture d’une large gamme d’appareils à pression pour vos installations industrielles, tels que :

- Séparateurs d’ammoniac

- Réservoirs d’ammoniac haute pression

- Cuves de stockage de liquides

- Réservoirs ou séparateurs de condensats pour applications vapeur

- Et d’autres applications spécifiques

En particulier si vous avez besoin d’un appareil complet, intégrant des mesures de niveau et/ou de pression, différents organes de service ainsi que des soupapes de sécurité directement montées sur l’appareil. Contactez-nous pour recevoir un devis adapté à vos exigences.

Tous nos appareils sont conçus conformément à la Directive Équipements Sous Pression (DESP) et sont livrés avec l’ensemble des certifications requises selon la réglementation européenne.