Research & Development

We create new technologies for a constantly changing society.

Beyond refrigeration

Ammonia absorption technology extends beyond refrigeration plants, enabling innovative applications such as the Kalina cycle for low-temperature power generation, akin to organic Rankine cycles (ORC), as well as various configurations for heat pumps—particularly when integrated with compressors to achieve high-temperatures with enhanced efficiency. Additionally, this technology can be utilized in desalination plants to boost operational efficiency, among numerous other potential applications.

This is why, from the very beginning of our venture, we have dedicated a significant part of our efforts to research and development activities. Due to our commitment and the high degree of innovation in these efforts, we have been rewarded with mentoring support and funding from the German government.

Developing the heat pump technology of the future

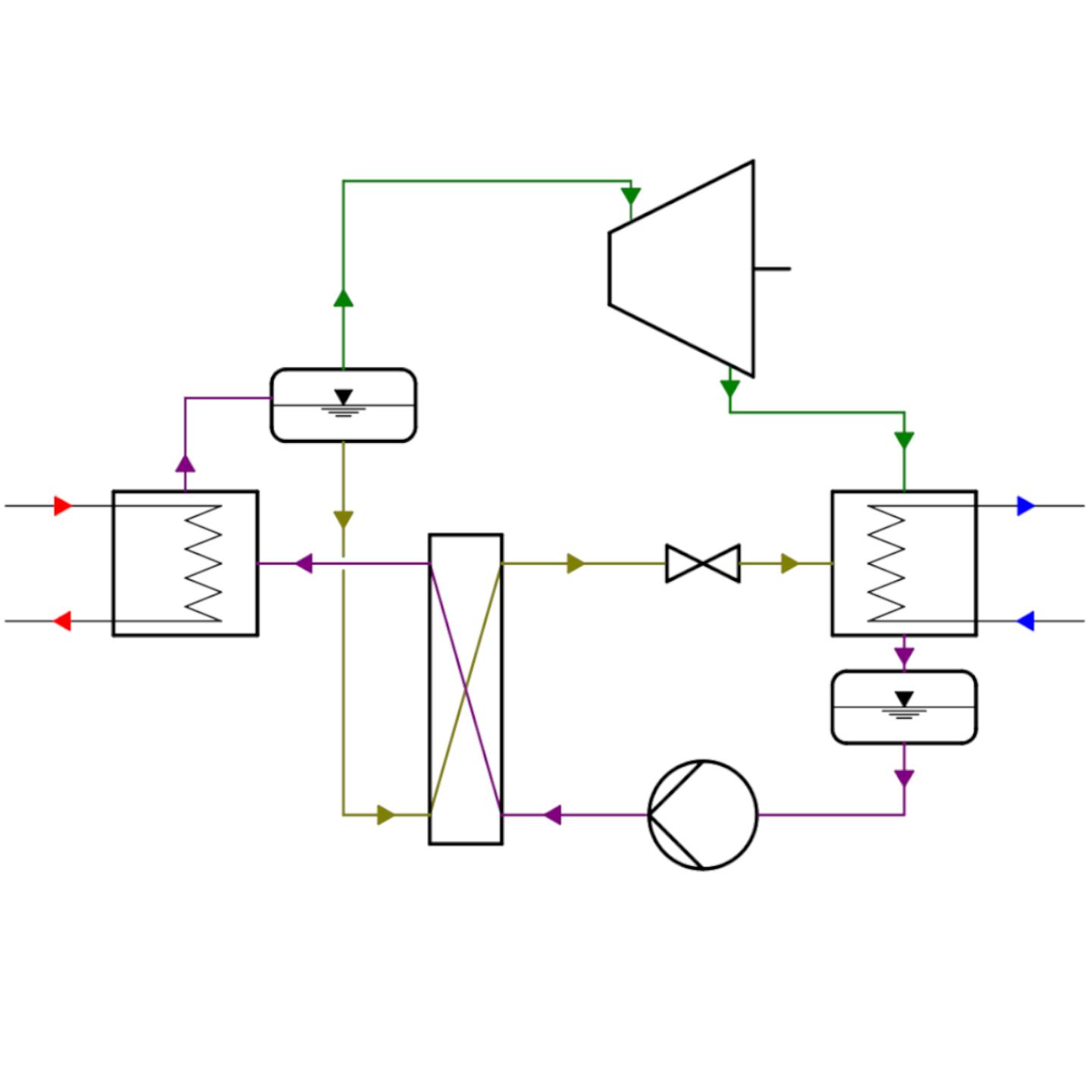

Introducing the combined Absorption Compression Heat Pump (ACHP)

This heat pump merges the technologies of an absorption system and vapor compression heat pump using a zeotropic mixture of ammonia and water as working fluid. As a result, heat is extracted and released at non-constant temperature glides. The required compression ratio can be reduced, when compared with conventional vapor compression heat pumps utilizing single fluid refrigerants, by adjusting the concentration of ammonia to the given boundary conditions. These characteristics, combined with the ability to achieve high sink temperatures above 150°C at large temperature lifts and high coefficients of performance (COP), lead to the ACHP system being a valuable solution for high temperature heat supply in the industry.

Some advantages of the ACHP towards a conventional compression heat pump are:

- high COP’s as result of gliding temperature

- low working pressures of less than 25 bars at sink temperature of around 150°C

- high temperature lifts from 75 K and more

- natural refrigerants with ODP & GWP = 0 (R717 & R718)

The Kalina cycle

The Kalina process is a thermodynamic cycle that uses a binary mixture of ammonia and water to generate electricity from heat. This cycle is comparable to the Rankine process, which is used, for example, in coal-fired power plants. The differences between these processes arise from the use of different working fluids. The Rankine process uses water as its working fluid, while in the case of the Organic Rankine Cycle (ORC), an organic chemical is used.

The Kalina cycle is particularly applicable for utilizing energy from industrial waste heat, geothermal heat, and solar thermal heat, allowing for higher thermodynamic efficiency than the Rankine cycle at moderate temperature differences and low-temperature heat sources. On the other hand, it provides greater flexibility than the Organic Rankine Cycle due to its ability to achieve dynamic concentration shifts, thereby enabling flexible adjustments to the boiling and absorption temperatures within the process.